11.2.

LET-OFF ADJUSTMENT

| The

information presented here is for educational purposes only. Please consult

a professional gunsmith before and after conducting any work on a firearm......

In other words be smart about it, and use this info intelligently.

|

11.2.1. General

Only

the armorer trained on the assault rifle is authorized to undertake let-off

adjustments.

Only

the armorer trained on the assault rifle is authorized to undertake let-off

adjustments.

The let-off is correctly adjusted if the let-off

cam of the sear lies upon the let-off spring arm and the sear notch is still

only slightly engaged with the hammer notch.

During

let-off adjustment, the hammer may not strike against the trigger housing.

The let-off is to be adjusted so that it is clearly

felt with the winter trigger.

|

|

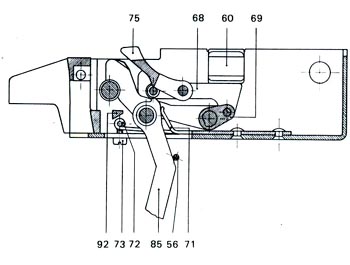

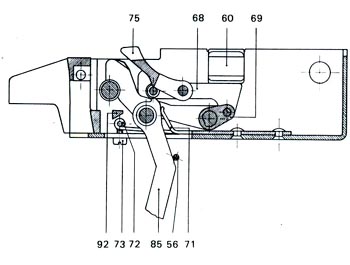

Seriefeuersperre,

Winterabzug und Druckpunktvorriclitung

56 Anschlagstift

60 Seriefeuersperre

68 Winkelhebel mit

Stift

69 Zwischenhebel

71 Federarm fOr Winterabzug

72 Druckpunktfederarrn

73 Druckpunktreguliermutter

75 Seriefeuerklinke

85 Winterabzug

92 Druckpunktnocken

der Abzugstange

|

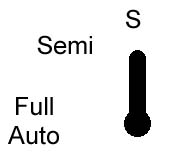

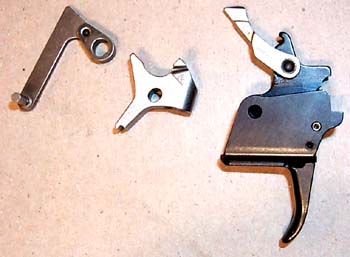

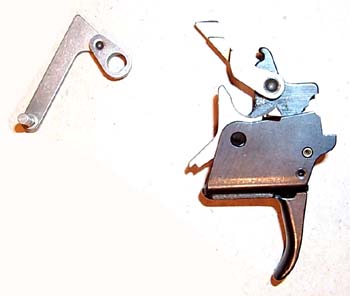

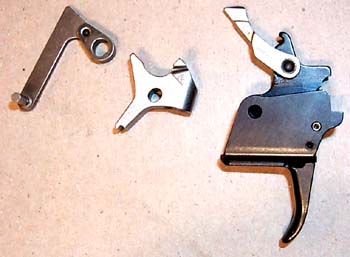

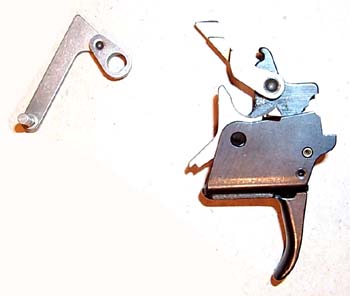

(Above

Left) Trigger group, shown for clarity without sear and trigger. Part

#60 is the white tab that signifies a semi-auto rifle. (Above) Diagram

depicts actual safety positions. |

11.2.2.

Carrying Out the Adjustment

Sequence of Tasks!

1) Unload weapon!

2) Let-off inspection by the armorer

3) Remove trigger mechanism from the weapon

4) Inspection of trigger components (in detail, if necessary)

5) Mount clamping lever for let-off adjustment and clamp until the let-off

adjustment nut protrudes from the hole in the trigger housing

6) With special socket wrench, turn the let-off adjustment nut as appropriate

7) Insert trigger mechanism (hammer cocked)

8) Re-inspect let-off on the assembled weapon

9) Carry out functional inspection accord 4

ng to paragraph 10.1.2.

Note:

|

Trouble

|

Remedy

|

|

Let-off

drags, or the hammer cannot be released:

|

Tighten

let-off adjustment nut

|

|

Let-off

too weak or not present:

|

Loosen

let-off adjustment nut

|

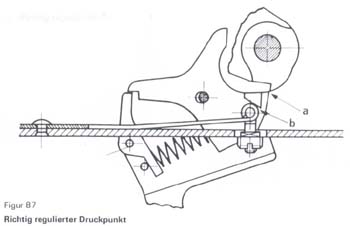

Figure 86

Adjusting

the let-off

A.

Correctly adjusted let-off

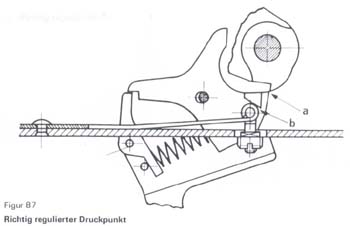

Figure

87

Correctly adjusted let-off

The let-off cam of the sear (b) presses against

the let-off spring arm. The sear and hammer notches (a) are still only slightly

engaged.

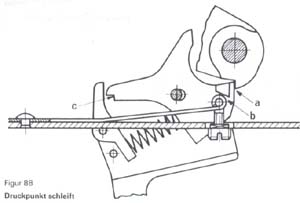

B. Unadjusted let-off

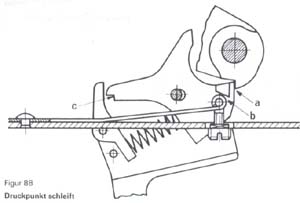

Figure

88

Let-off drags

The let-off cam of the sear (b) presses against

the let-off spring arm. The sear and hammer notches (a) are too strongly engaged.

If the let-off adjustment nut is loosened all

the way, the release pawl can no longer engage the sear (c).

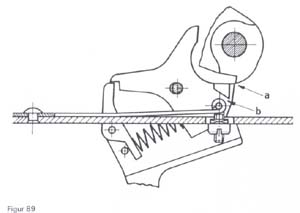

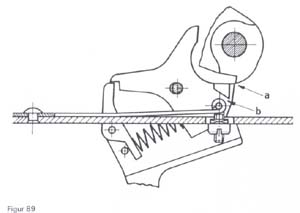

Figure 89

Let-off too weak (or no let-off present)

The let-off cam of the sear presses against

the let-off spring arm. The sear and hammer notches, however, are too slightly

engaged (the let-off is too weak).

If the let-off adjustment nut is tightened

all the way, the letoff cam of the sear does not reach the let-off spring

arm (b). The sear notch releases the hammer (a) (no let-off is present).

Last Modified on

March 17, 1999

aalbert@biggerhammer.net

Only

the armorer trained on the assault rifle is authorized to undertake let-off

adjustments.

Only

the armorer trained on the assault rifle is authorized to undertake let-off

adjustments.